Contact Us

DSA-China Electronic Technology Co.,Ltd.

Room 1101-1106, No.333, YiShan Road,

Xuhui District, Shanghai, China

200030

solutions@dsa.com.cn

Modern vehicle architectures are shifting toward centralised computing and software-defined functionality. With this transformation, the diagnostic landscape faces new demands: distributed applications, dynamic behaviour, service-oriented communication, and continuous software deployment.

Conventional diagnostic protocols such as UDS were developed for static, ECU-centric environments. These approaches lack the flexibility needed to address software-driven components, high-performance computing units (HPCs), and domain-based vehicle architectures.

Service-Oriented Vehicle Diagnostics (SOVD) provides a unified, API-based interface to access diagnostic information and services. It supports dynamic software systems, enables integration into cloud-based diagnostic workflows, and allows consistent access across engineering, production, and aftersales environments.

Importantly, SOVD is not limited to future vehicle platforms. It can already be introduced today by deploying the protocol stack on an external diagnostic device, enabling standardised access to existing vehicle ECUs. This makes SOVD a practical and forward-compatible entry point for modernising diagnostic systems without requiring immediate changes to the in-vehicle architecture.

By adopting SOVD, OEMs and suppliers can streamline diagnostic access across diverse platforms, reduce implementation complexity, and prepare their vehicle architectures for future software-centric requirements.

A consistent, service-based API supporintg proximity, remote, and onboard diagnostics for uniform workflows.

Provides machine-readable capability descriptions and schema definitions to enable dynamic client behaviour without prior static coding.

Enables access to distributed services, applications, and logs in HPC platforms — beyond the capabilities of traditional ECU-centric diagnostics.

Continuously developed to address new diagnostic use cases, enabling future-proof integration into evolving vehicle architectures.

Software-defined vehicles (SDVs) introduce diagnostic challenges that exceed the design boundaries of conventional protocols such as UDS. These include:

Static fault models: UDS requires predefined fault codes, making it difficult to represent dynamic or service-related failures in modern software environments.

Limited diagnostic abstraction: UDS is tightly coupled to ECU memory layout and internal signals, with little support for abstract or logical service interfaces.

Inadequate support for HPCs and services: High-performance computing units and SOA-based components introduce distributed diagnostics, runtime variability, and service monitoring needs that UDS was not designed to handle.

Constraints on remote diagnostics: Security, session handling, and timing assumptions in UDS make it challenging to implement robust remote diagnostics over cloud or mobile networks.

Fragmented tooling and integration: UDS implementations often require custom extensions and separate toolchains per use case, complicating consistent diagnostic workflows across engineering, production, and aftersales.

SOVD enables a modern diagnostic architecture that supports cloud integration, dynamic software management, and consistent diagnostics across all vehicle lifecycle phases:

Cloud-native integration: Diagnostic workflows can be seamlessly integrated into IT backends and OTA platforms, with secure access from remote environments.

Server-side diagnostic logic: All diagnostic interpretation and control reside on the SOVD server — and thus typically on the vehicle — reducing client-side complexity and ensuring consistent execution across platforms.

Diagnostic function abstraction: Complex, context-sensitive diagnostics can be exposed as reusable functions, decoupled from ECU specifics or static definitions.

Support for distributed architectures: SOVD allows diagnostics across HPCs and cloud–integrated vehicle systems, including interlinked services, containers, and dynamic workloads.

Extended diagnostic access: In addition to traditional faults and measurements, SOVD enables retrieval of log files, runtime traces, and other structured diagnostic artefacts especially required by service-oriented architectures.

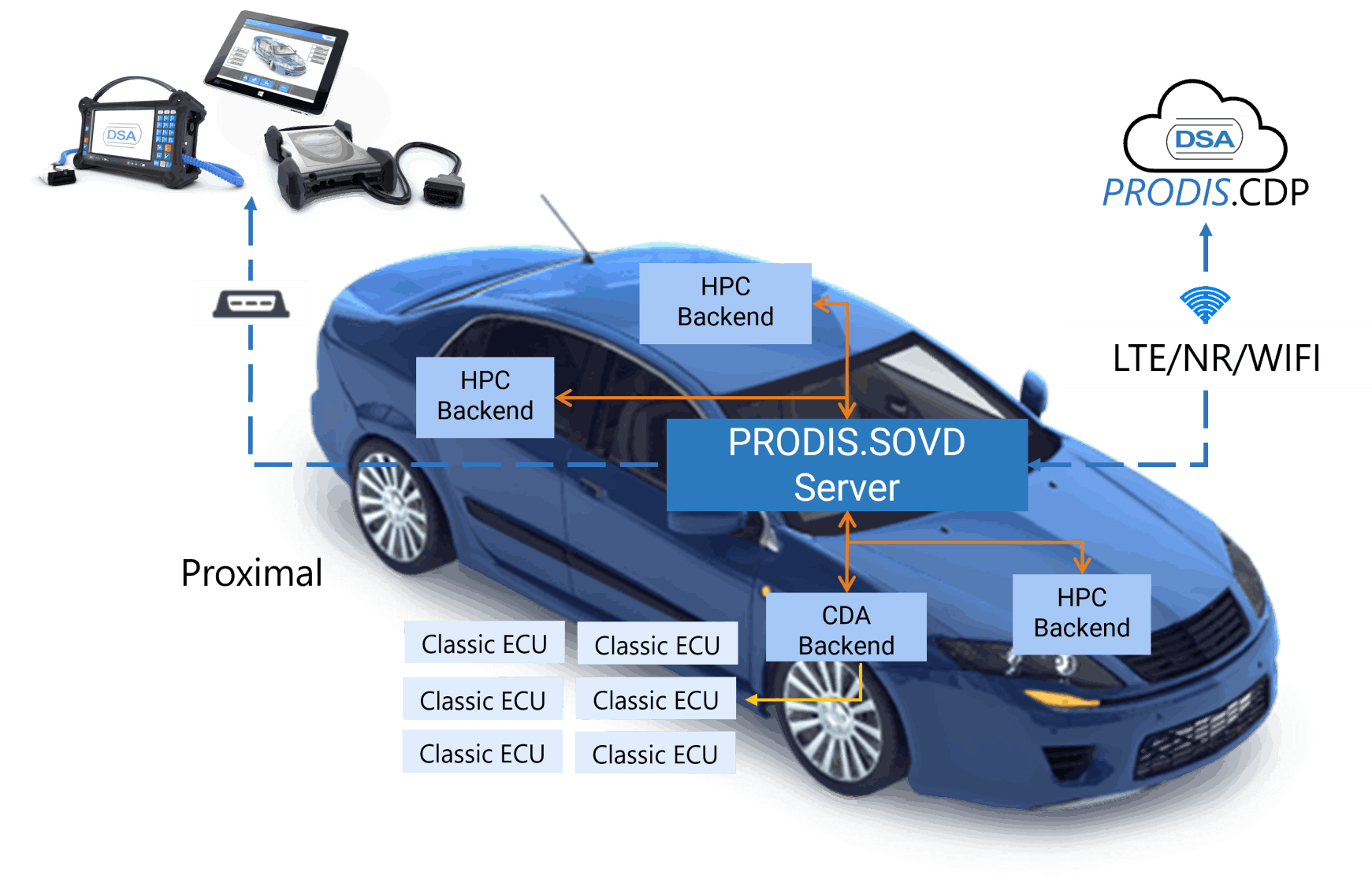

DSA's PRODIS.SOVD is a fully standard compliant implementation of the SOVD API and acts as the central gateway between diagnostic clients and the in-vehicle system architecture — supporting both modern HPC domains and legacy ECU networks.

Designed for supporting all vehicle lifecycle phases — engineering, production, aftersales, and remote access — the server enables a unified diagnostic interface, independent of physical connectivity or system topology. This includes seamless integration into over-the-air (OTA) update platforms and cloud-based workflows.

PRODIS.SOVD communicates natively with HPCs to execute software-centric diagnostics. For traditional control units, the integrated Classic Diagnostic Adapter (CDA) provides protocol translation between SOVD and legacy protocols such as UDS, J1939, or KWP. This allows existing diagnostic logic to be preserved while modernising the diagnostic interface.

By bridging both domains — service-oriented and legacy — PRODIS.SOVD enables OEMs and suppliers to adopt the SOVD standard today without requiring immediate changes to vehicle hardware or diagnostic workflows.

In production and aftersales environments, diagnostic tools are physically connected to the vehicle. With SOVD, a proximity client can access central and distributed vehicle functions through a unified interface — supporting fault localisation, ECU and HPC configuration, actuator tests, and end-of-line validation. This enables consistent workflows across testing and commissioning stages.

SOVD enables secure remote access to diagnostic functions via backend or cloud systems. Typical use cases include workshop pre-diagnosis, remote support, fleet condition monitoring, activation of vehicle services, and execution of software updates. Through PRODIS.SOVD, these tasks are abstracted from underlying protocols and integrated into cloud-based services.

Diagnostic applications can run directly on in-vehicle HPCs, leveraging local compute resources. Via the SOVD API, they access runtime signals, trigger diagnostic procedures, and collect information for predictive maintenance — independent of external test equipment.

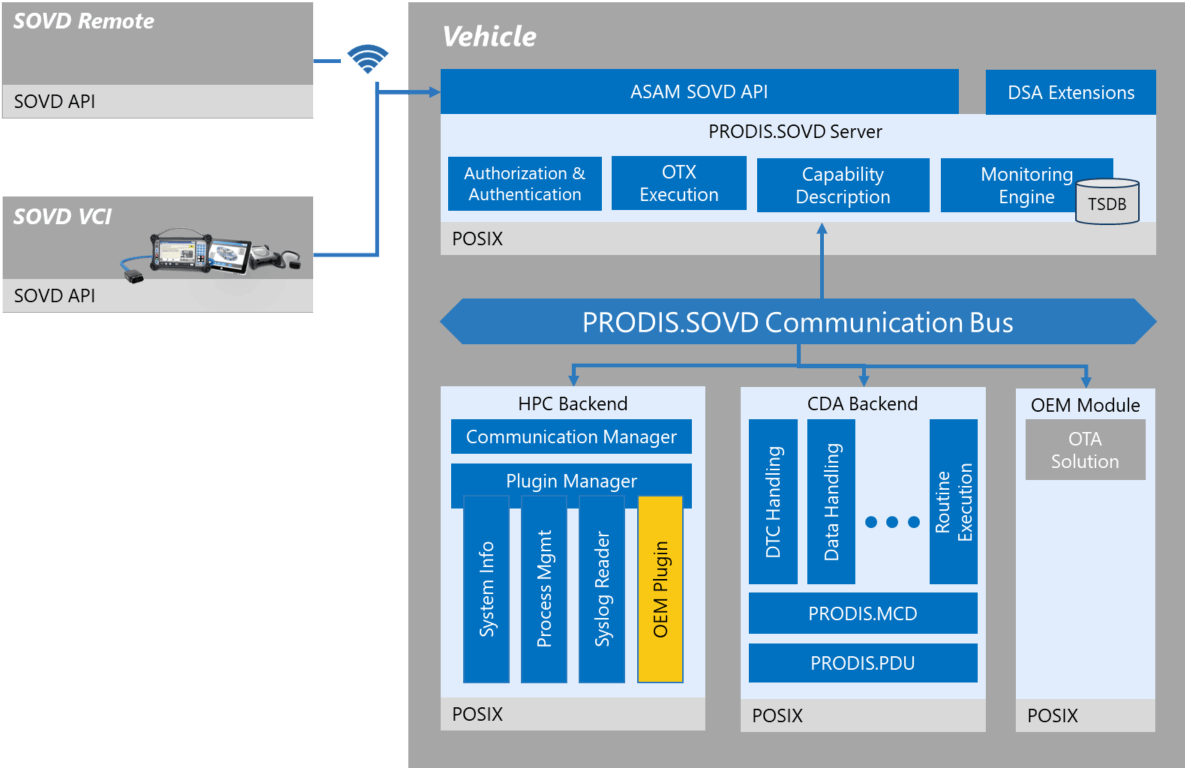

The architecture of PRODIS.SOVD is designed to support diagnostic access across modern service-oriented platforms and traditional ECU networks. At its core, the SOVD server acts as a standardised gateway between diagnostic clients and diverse in-vehicle systems.

Through modular backends, the server interfaces with HPC-based software platforms as well as classic ECUs using legacy protocols. This hybrid architecture enables a gradual migration towards service-oriented diagnostics, while maintaining full compatibility with existing production and aftersales tooling.

DSA's solution supports POSIX-compatible operating systems such as Linux, QNX, or Android, and supports integration into any OEM-specific environment.

The PRODIS.SOVD Server implements the ASAM SOVD API and provides a unified diagnostic interface for proximity, remote, and on-board use cases.

All diagnostic requests are managed centrally, allowing consistent execution across clients and use cases — independent of connectivity type or platform.

The Classic Diagnostic Adapter (CDA) backend bridges SOVD with legacy ECU protocols including UDS, J1939, and KWP. It is built on ISO 22900-2/3 compliant components, supporting standardised diagnostic data handling and tooling interoperability.

This enables the reuse of existing diagnostic content and provides a smooth migration path.

The HPC backend interfaces with high-performance computing platforms and service-oriented vehicle functions. By this, it provides diagnostic access to distributed software components, runtime states, performance metrics, and logs — enabling dynamic, system-level diagnostics beyond ECU boundaries.

This backend supports containerised services, middleware platforms, and domain controller architectures common in SDVs.

PRODIS.SOVD supports full integration with diagnostic workflows and backend systems. It includes OTX (ISO 13209) support for portable test sequences, and offers compatibility with third-party SOVD servers and OEM OTA platforms.

This allows scalable deployment across vehicle programmes and existing infrastructures.

DSA supports OEMs and suppliers in defining their specific SOVD architecture — including diagnostic service models, capability description formats, and integration into existing toolchains. Our consulting spans system design, compliance guidance, and rollout planning across vehicle programmes.

We assist ECU and system suppliers in creating machine-readable SOVD capability descriptions. These descriptions support dynamic service discovery and enable efficient implementation of structured, testable diagnostic interfaces across platforms and variants.

Our toolchain spans the entire vehicle lifecycle — from R&D to aftersales — and includes SOVD clients, test environments, simulations, and remote diagnostic platforms. We provide robust backend components for OTA workflows, fleet diagnostics, and workshop integration.

DSA enables in-vehicle deployment of the SOVD protocol stack, including support for both HPC-based diagnostics and classic ECUs. This ensures compatibility with existing UDS infrastructure while enabling a smooth transition to service-oriented architectures.